Managing AM's Details with a Manufacturing Execution System

Like any other production process, additive manufacturing needs tools to manage data. Bluestreak’s manufacturing execution system (MES) is one option for companies focused on production.

Share

Read Next

Additive manufacturing (AM) has been rapidly overcoming hurdles in its race to become a production technology. The machines have gotten faster and more predictable; materials have gotten better; design and control software solutions have advanced. But one of the remaining hurdles—and one that individual companies are often working out for themselves—is standardization. How do you ensure predictable parts in a process that has so many parameters? Even more difficult, how do you validate that process and earn the certifications necessary to compete in the many industries that can benefit from AM?

Manufacturing resource planning (MRP) and enterprise resource planning (ERP) programs are one potential tool on the pathway to standardization, one that conventional manufacturing processes often rely on. But existing tools are not necessarily optimized for AM production control.

“Most of the MRP and ERP systems that are out there were designed for a subtractive manufacturing process, and they don’t have the capability to track things that are in an additive manufacturing process,” says Ron Beltz. Beltz is director of strategic accounts at Bluestreak, the developer of an eponymous software suite that functions as a real-time production control and monitoring system. Originally developed for the heat-treating industry, Bluestreak has evolved over time to offer different modules and customizations suited to different industry segments and operating environments, the latest of which is an Additive Manufacturing Edition designed for companies using AM in production.

A Manufacturing Execution System (MES) for AM

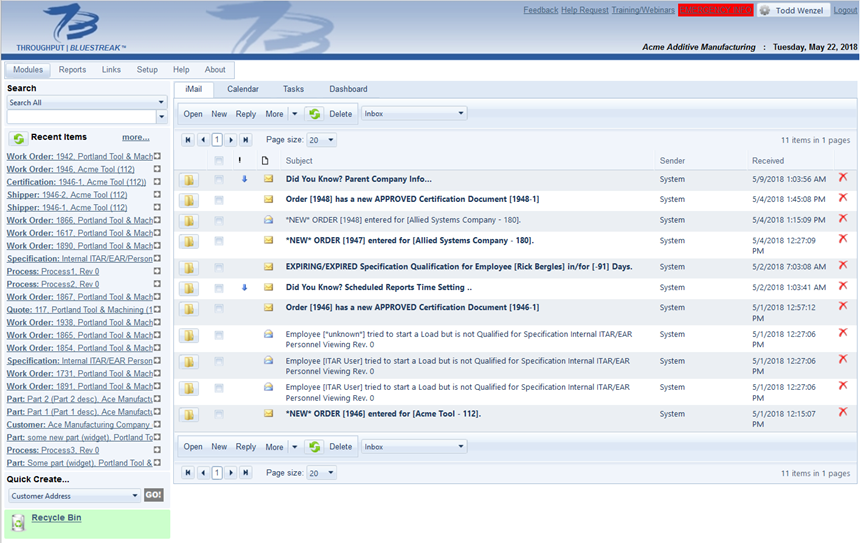

At its core, Bluestreak is a manufacturing execution system (MES) and quality management system (QMS) platform capable of tracking everything from incoming orders to work in progress to delivery confirmation. Users pay a monthly licensing fee for single-user up to enterprise-wide access, and can integrate Bluestreak with an existing ERP system. Companies can choose which modules they want to implement and track what they want in as much detail as necessary; more advanced customizations can be developed by Bluestreak when required.

“Each company sets up its own equipment in its production facility, and they set up their own ‘recipes’ or processes that they need to go through on every particular part that they create,” Beltz says. “They are in control of how granular they want to get with production control and quality control.”

Additive manufacturing has some unique concerns compared to other, more conventional processes that aren’t necessarily supported in standard MRP and ERP programs. For instance, many 3D-printed parts have stipulations about the state of the material that can be used. Some jobs may require virgin powder, while others may allow mixing older, recycled powder in with new up to a certain ratio. Bluestreak offers the ability to track those material batches and blends, and users can even add parameters and quality characteristics to work orders to prevent a job from being sent to a printer stocked with the wrong blend of material.

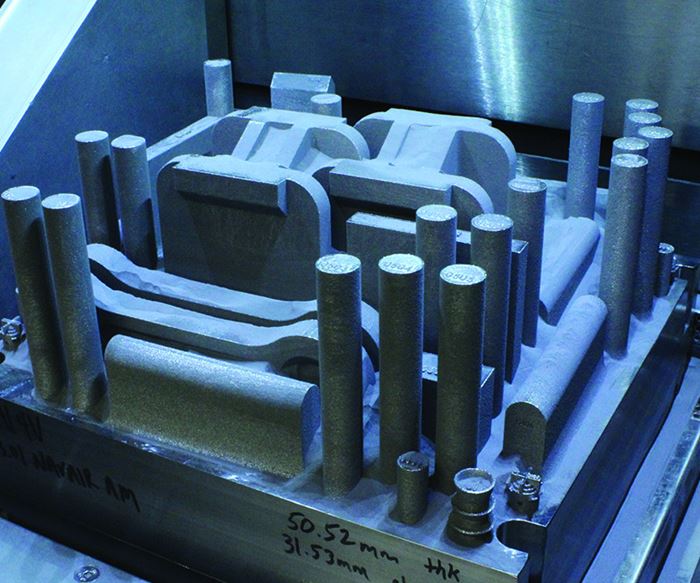

Another challenge particular to AM is the fact that most processes can build multiple parts at a time, allowing for different part numbers on the same build plate. The ability to track disparate parts being produced together is not necessarily available in conventional software packages, but the AM customizations in Bluestreak support this. Through the work in progress (WIP) screen, users can track the progress of each part with time-stamped documentation during the build, and the MES can even help automatically schedule similar parts into the same batch on an appropriate machine.

“Bluestreak also supports unique serial numbers for each part being printed and tracks each serial number through the process, including any involved in nonconformances, which is a critical requirement for such industries as aerospace, aviation and medical,” Beltz says.

Automation and Beyond

But beyond tracking material and parts, the software also enables some level of additive manufacturing automation through a function called IntelliPlan. IntelliPlan simplifies the process from work order to manufacturing, walking users through whatever steps or parameters the customer has opted to require for each job. From there, the software can be used to batch parts out to available machines on a recommended schedule. Users can override the recommendations with the right permissions, but the advantage of IntelliPlan is that it can reduce the amount of time humans must spend on the task of building and updating a part process while conforming to detailed specification requirements.

Ultimately, Bluestreak sees this shift of mental labor from humans to computers as one of the main benefits of its software. OEMs can set material, machine and build parameter requirements that will be embedded in the work order, reducing errors in communicating with manufacturers. Manufacturers can assign permissions to employees, permitting them to operate only machines they have been trained on, avoiding problems or even dangerous situations at the manufacturing level. All parties can gain direct insight into the progress of a particular job, right down to the individual part.

...traceability has considerable potential for bringing validation and repeatability to additive manufacturers.

This last point, traceability, has considerable potential for bringing validation and repeatability to additive manufacturers, Beltz says. The software can serve as “the complete audit trail,” he says, from work order through delivery. If companies are specific and thorough in setting up their “recipes,” the MES can ensure that these procedures are executed. For example, ISO 9001:2015 requires a risk analysis for each distinct part; Bluestreak users can create risk assessment templates for their business and set up the system so that users must complete the form before the quote can be printed or emailed. That kind of consistency is key for manufacturers seeking to earn certifications, and beneficial in the audit process.

“We’ve heard from auditors that say it cut their audit times in half,” Beltz says. “Where sometimes they might be onsite for a company for a whole week, with Bluestreak they might be there only a day and a half.”

With so many variables in AM, having a thorough record of past jobs is also helpful to manufacturers as a way of ensuring consistency and quality. “If a customer says, ‘Hey, do the same thing you did last time,’ the shop can bring up that original work order and copy it over to a new one with all the processing steps,” Beltz says. “They know they’re doing exactly the same processing they did last time.”

Related Content

Casting With Complexity: How Casting Plus 3D Printing Combine the Strengths of Both

Aristo Cast is advancing a mode of part production in which casting makes the part, but 3D printing enables the geometry.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreAluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More

.jpg;width=70;height=70;mode=crop)