Elementum 3D awarded SBIR Phase I grants from NASA and US Navy

July 5, 2021

Elementum 3D, Erie, Colorado, USA, was awarded two SBIR Phase I in May and June 2021 by NASA and the US Department of the Navy, respectively.

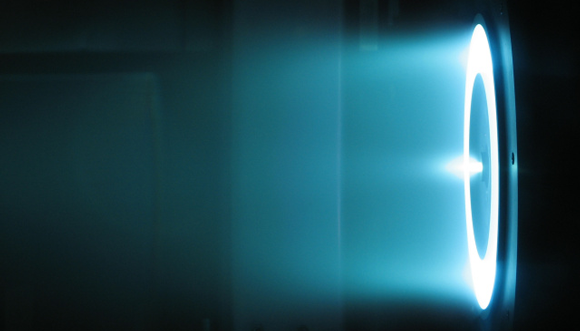

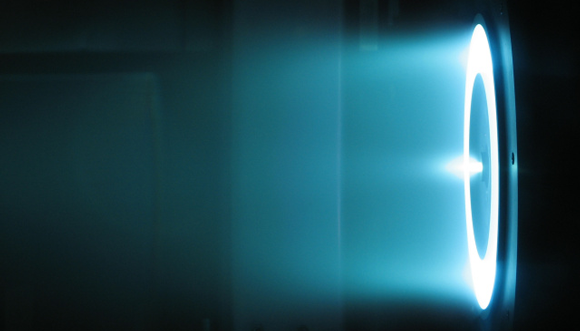

The first SBIR is centred around the development of additively manufactured soft magnetic materials for large diameter Hall-effect thrusters. As in-space electric propulsion systems are becoming increasingly important to interplanetary missions, NASA is searching for better manufacturing methods in producing large diameter Hall-effect thrusters with the necessary magnetic properties and structural robustness. Elementum 3D will be partnering with Altius Space Machines in the development of AM iron-cobalt alloys, Additive Manufacturing processes, and post-processing to achieve the needed performance for these thrusters, as well as other space and terrestrial uses.

The second SBIR contract was awarded for the ‘Controlling Microstructure Through Nucleation – The Key to Designing the Next Generation of High-Performance Alloys for Additive Manufacturing’ project. In this, Elementum 3D is partnering with Dr Jonah Klemm-Toole, Colorado School of Mines, and Special Aerospace Services, in developing a modelling framework to linking alloy chemistry, AM processing, thermal history, microstructure and defect development and mechanical properties.

Elementum 3D’s rapid experimental alloy development (READ) process will be used to provide extensive experimental validation of the model predictions to allow for iterative model development and improvements. The validated model will be used as a guide for the development of new designed-for-AM nickel superalloys, copper alloys, and more.